What is a Vacuum Cooling System?

Focusun Vacuum Coolers cool down products to their optimum storage temperature in the most effective and efficient way by creating a vacuum. Focusun Vacuum Cooling Solutions are of excellent quality and come in different models for various uses. Moreover, each machine can be customized to meet your specific requirements. Focusun vacuum coolers can improve the cooling rate, reduce the loss of nutrients and keep original texture, color, sensory properties and nutrition of products, which can significantly increase the shelf life of products as well as reducing the health risk caused by organism growth. Our vacuum coolers are widely used to cool products in the ready food and catering industry and also in the fresh produce and post harvest sector, such as leafy vegetables and fresh-cut flowers.

Benefits and features of Focusun Vacuum Coolers

Vacuum Cooling technology is based on the phenomenon that water starts boiling at lower temperatures as the pressure decreases. The boiling process takes away heat from the product. As a result, products can be cooled down within a short time. The advantages of Focusun Vacuum Cooler are as follows:

- Rapid and uniform cooling: it usually takes 20 – 30 minutes to reach required refrigeration temperature. The surface and core of the vegetable can reach exact the same temperature after vacuum cooling even the micro-perforated, packed products.

- Clean and sanitary: in the vacuum, products are sterilized effectively without spreading of micro-organisms, especially water borne microorganisms and cross-contamination.

- Thin-layer drying effect: unique effect to cure slight damages on the surface and inhibit the expansion on fresh products.

- High accuracy: equipped with imported temperature and humidity controllers, Focusun Vacuum Coolers ensure excellent usability and operation.

- vacuum cooler for vegetables&fruits

- vacuum cooler for flowers

- vacuum cooler for ready food

- Overview

- Specifications

- Photos

- Videos

- Our Clients

- Enquiry - Buy Here

Focusun Vacuum Cooler for vegetables & fruits

Focusun Vacuum Cooler is the most efficient way to reduce the internal temperature of products from field temperature to ideal storage temperature. It can significantly improve the cooling rate, reduce the consumption of nutrients and keep original texture, color, sensory properties and nutrition of products, and therefore the shelf life of products can be greatly extended. Focusun vacuum cooler has been widely used for cooling products in food and catering industry and also in the fresh produce and post harvest sector now.

| NO. | MODEL | TYPE | AMOUNT OF EACH TREATMENT | AMOUNT OF EACH HOUR |

|---|---|---|---|---|

| 1 | FVC-01S | Single Bin Model | 200 kg | 400 kg |

| 2 | FVC-01P | Single Pallet Model | 600 kg | 1200 kg |

| 3 | FVC-02P | Two Pallet Model | 1200 kg | 2400 kg |

| 4 | FVC-04P | 4 Pallet Model | 2400 kg | 4800 kg |

| 5 | FVC-06P | 6 Pallet Model | 3600 kg | 7200 kg |

| 6 | FVC-08P | 8 Pallet Model | 4800 kg | 9600 kg |

| 7 | FVC-10P | 10 Pallet Model | 6000 kg | 12000 kg |

| 8 | FVC-12P | 12 Pallet Model | 7200 kg | 14400 kg |

Product details and specifications about Vacuum Cooler for vegetables & fruits

Focusun Vacuum Coolers are applied for fresh produce, cut-flowers and also the ready food. We offer different models and some tailored options for specific requirements. Our professional R&D team provides scientific refrigeration technical design and solutions. Besides, to ensure decades of trouble-free operation, 80% main components are from world renowned suppliers.

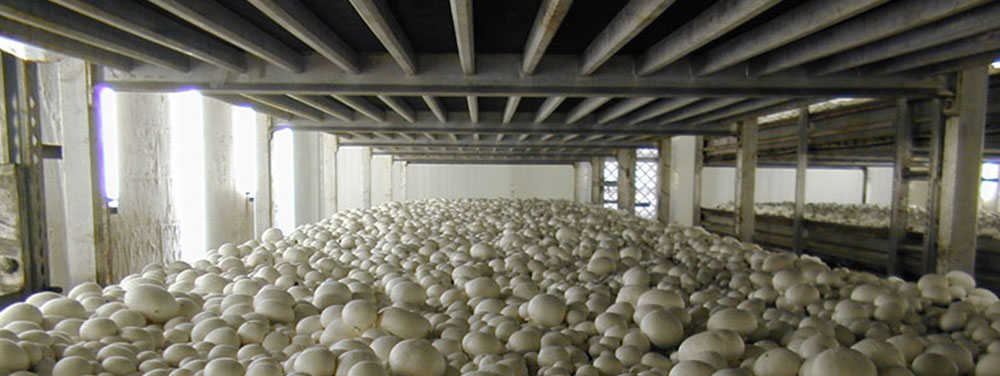

Vacuum Cooler for vegetables & fruits

Vacuum Cooler for vegetables & fruits Vacuum Cooler for vegetables & fruits

Vacuum Cooler for vegetables & fruits Vacuum Cooler for vegetables & fruits

Vacuum Cooler for vegetables & fruits Vacuum Cooler for vegetables & fruits

Vacuum Cooler for vegetables & fruits Vacuum Cooler for vegetables & fruits

Vacuum Cooler for vegetables & fruits Vacuum Cooler for vegetables & fruits

Vacuum Cooler for vegetables & fruits Vacuum Cooler for vegetables & fruits

Vacuum Cooler for vegetables & fruits Vacuum Cooler for vegetables & fruits

Vacuum Cooler for vegetables & fruits

Photos of Vacuum Cooler for vegetables & fruits

Focusun Vacuum Cooler is constructed from shot blasted and painted mild steel beam with 304 stainless steel shell. The type of door opening can be customized from swing door or horizontal sliding door. The Vacuum Cooler consists of two parts: vacuum chamber and electrical unit. The temperature can be settled by pressure transducer.

Videos of Vacuum Cooler for vegetables & fruits

Focusun Vacuum Coolers are equipped with imported temperature and humidity controllers which ensure the high accuracy, excellent usability and operation. User-friendly design makes the machine easy to operate and maintain on the spot. The whole cooling process usually takes 20-30 minutes to reach the optimum storage temperature, enjoying the benefits of rapid and uniform cooling.

Clients who purchased our Vacuum Cooler for vegetables & fruits

Testimonials

We are very impressed with the high quality of our vacuum cooler. Our cooperation with Focusun will definitely continue in the future.

Ni's (Hubei, China)

The technical and after-sales support is superb. We hope to continue our business corporations and will recommend Focusun for your ice cooling solutions.

The Container (USA)

Our machine works perfect and we have no complaints. We are satisfied with their technical knowhow and professionalism of Focusun.

Restaurant At Halifax (Canada)

At first I wasn't sure if buying a China-made vacuum cooler was advisable. But I am happy with my machine.

James Baffour (Accra)

This machine was cost-efficient and it remains reliable up till today. I will recommend Focusun products.

Shuktara Nature Retreat (Bangladesh)

Send us your Enquiries, request Quotations or just Buy Here

Use our form below to get special information and our customer service team will quickly respond to you with an offer for your customized ice machine. Leave your number if you want us to call you back. If you don't like forms for any reason, you can simply send us an email to enquiry@focusun.com with all of your requirements and we will just be as happy to respond.

- Overview

- Specifications

- Photos

- Videos

- Our Clients

- Enquiry - Buy Here

Focusun Vacuum Cooler for flowers

Focusun Vacuum Coolers adopt special system to adapt the cooling of fresh cut-flowers. Flower vacuum cooling technology controls the temperature and humidity in vacuum chamber which are determined by the physiological characteristics, sensitivity and humidity of flowers. For those flowers which need to be cooled to an ultra-low temperature, Focusun provide hydro vacuum cooler to avoid excessive moisture loss and keep the freshness.

| NO. | MODEL | TYPE | AMOUNT OF EACH TREATMENT | AMOUNT OF EACH HOUR |

|---|---|---|---|---|

| 1 | FVC-01S | Single Bin Model | 150 kg | 300 kg |

| 2 | FVC-01P | Single Pallet Model | 450 kg | 900 kg |

| 3 | FVC-02P | Two Pallet Model | 900 kg | 1800 kg |

| 4 | FVC-04P | 4 Pallet Model | 1800 kg | 3600 kg |

| 5 | FVC-06P | 6 Pallet Model | 2700 kg | 5400 kg |

| 6 | FVC-08P | 8 Pallet Model | 3600 kg | 7200 kg |

| 7 | FVC-10P | 10 Pallet Model | 4500 kg | 9000 kg |

| 8 | FVC-12P | 12 Pallet Model | 5400 kg | 10800 kg |

Product details and specifications about Vacuum Cooler for flowers

Focusun Vacuum Coolers has extensive application, especially suitable for fresh produce, fresh cut-flowers and also the cooked food. Different capacities and some tailored options such as trolley loading systems are available for specific requirements. With years of design and manufacturing design, our professional R&D team can offer you the scientific refrigeration technical design and solutions.

Photos of Vacuum Cooler for flowers

Focusun Vacuum Coolers are constructed from shot blasted and painted mild steel beam with 304 stainless steel shell. The type of door opening can be customized from swing door to horizontal sliding door. The whole Vacuum Cooler consists of two parts: vacuum chamber and electrical unit. The cooling temperature can be settled by controlling the vacuum level via pressure transducer.

Videos of Vacuum Cooler for flowers

Focusun Vacuum Coolers for flowers are applicable in all kinds of flowers, and in particular those with high respiration, such as roses and carnations. Equipped with imported temperature and humidity controllers, our Vacuum Coolers enjoy the reputation of the high accuracy, excellent usability and operation.

Clients who purchased our Vacuum Cooler for flowers

Testimonials

Focusun ice storage in a 40 foot container are powered by solar energy for our business. Great product; we are very satisfied with our product.

Omar Abdoul (Nigeria)

Thanks to Focusun, we were able to store up more fresh products, expanding the life of our fresh seafood products.

Grand Bay (Malaysia)

Great product, energy efficient and friendly customer service. I will surely buy this product again in the future.

The Braai Shack (South Africa)

The ice storage is energy efficient and the power consumption is moderate considering the power supply problems in our area.

Loud Nimako Jr. (Ghana)

I bought 2 small sized mobile ice storage to allow better transportation and distribution of my ice products to my clients. This has given my business a new shape and better revenue generation. Thanks guys.

Demi Lee (UK)

Send us your Enquiries, request Quotations or just Buy Here

Use our form below to get special information and our customer service team will quickly respond to you with an offer for your customized ice machine. Leave your number if you want us to call you back. If you don't like forms for any reason, you can simply send us an email to enquiry@focusun.com with all of your requirements and we will just be as happy to respond.

- Overview

- Specifications

- Photos

- Videos

- Our Clients

- Enquiry - Buy Here

Focusun Vacuum Cooler for ready food

For pre-cooled food, we adopt food grade stainless steel 304 to preserve the quality and security of food. Vacuum cooling systems can considerably shorter the cooling process, and therefore, inhibit the micro-organisms proliferation, extend the storage and shelf life. It is widely applied for steamed, boiled, fried and baked food, such as ready meat, soy products, fast food, bread and so on.

| NO. | MODEL | TYPE | AMOUNT OF EACH TREATMENT | AMOUNT OF EACH HOUR |

|---|---|---|---|---|

| 1 | FVC-01S | Single Bin Model | 150 kg | 300 kg |

| 2 | FVC-01P | Single Pallet Model | 450 kg | 900 kg |

| 3 | FVC-02P | Two Pallet Model | 900 kg | 1800 kg |

| 4 | FVC-04P | 4 Pallet Model | 1800 kg | 3600 kg |

| 5 | FVC-06P | 6 Pallet Model | 2700 kg | 5400 kg |

| 6 | FVC-08P | 8 Pallet Model | 3600 kg | 7200 kg |

| 7 | FVC-10P | 10 Pallet Model | 4500 kg | 9000 kg |

| 8 | FVC-12P | 12 Pallet Model | 5400 kg | 10800 kg |

Product details and specifications about Vacuum Cooler for ready food

FVC series of vacuum cooling machines are produced by absorbing advanced technology and experience of similar products at home and abroad. Focusun vacuum coolers are well-designed, economical, reliable, efficient, fully-automated and with low power consumption. Vacuum cooler equipment is the most suitable cooling way for ready food.

Photos of Vacuum Cooler for ready food

Focusun Vacuum Cooler adopt modular design which consists of two parts: vacuum chamber and electrical unit. The Vacuum Cooling Machines are constructed from shot blasted and painted mild steel beam with 304 stainless steel shell. Different door designs and condensing types are available. Choose from swing door, horizontal sliding door, air cooling, water cooling and evaporative cooling condenser to meet your specific requirements.

Videos of Vacuum Cooler for ready food

Compact and modular design simplifies the operation and the maintenance on spot. Moreover, equipped with remote control and monitoring equipment, our Vacuum Cooler not only facilitates the operation but also can quickly resolve equipment failures. We manufacture both standard Vacuum Cooler models and Hydro Vacuum Cooler Models.

Clients who purchased our Vacuum Cooler for ready food

Testimonials

Focusun ice storage in a 40 foot container are powered by solar energy for our business. Great product; we are very satisfied with our product.

Omar Abdoul (Nigeria)

Thanks to Focusun, we were able to store up more fresh products, expanding the life of our fresh seafood products.

Grand Bay (Malaysia)

Great product, energy efficient and friendly customer service. I will surely buy this product again in the future.

The Braai Shack (South Africa)

The ice storage is energy efficient and the power consumption is moderate considering the power supply problems in our area.

Loud Nimako Jr. (Ghana)

I bought 2 small sized mobile ice storage to allow better transportation and distribution of my ice products to my clients. This has given my business a new shape and better revenue generation. Thanks guys.

Demi Lee (UK)

Send us your Enquiries, request Quotations or just Buy Here

Use our form below to get special information and our customer service team will quickly respond to you with an offer for your customized ice machine. Leave your number if you want us to call you back. If you don't like forms for any reason, you can simply send us an email to enquiry@focusun.com with all of your requirements and we will just be as happy to respond.

Focusun ™ Vacuum Cooling machines are well-designed, economical, reliable, efficient, fully-automated and with low power consumption. For your reference, we have uploaded some videos of our various models. Please choose from Vacuum Coolers for vegetables & fruits, for flowers and for ready food to view more videos.

Focusun ™ reserves all rights to our videos. Our videos may be used for reference purposes only. For any other purpose, please inform us beforehand.

- Focusun vacuum cooler for ready food/cooked food

- Focusun Vacuum Cooler- precooling solution for flowers

- Focusun Vacuum Cooler with trolley loading system

- Focusun Vacuum Cooler Series for vegetables

- Snow Making System

- Concrete Cooling System

- Mine Cooling System

- 18T Containerized Water Chiller

- Fully-automatic Ice Packing Machine

Focusun ™ Vacuum Cooling machines are well-designed, economical, reliable, efficient, fully-automated and with low power consumption. For your reference, we have uploaded some photos of Vacuum Coolers for vegetables & fruits, for flowers and for ready food. Please remember that our Vacuum Coolers can be customized as per different customer's demands and situations.

Focusun ™ reserves all rights to our photos. Our photos may be used for reference purposes only. For any other purpose, please inform us beforehand.

Focusun ™ is the leading Chinese supplier of Vacuum Coolers. For your best Focusun experience, we keep improving and upgrading our services. Please watch videos of some frequently asked questions about Focusun, our product and services.

Also see the following answers on how to solve both common and complex problems with your Focusun products. We understand it may not always be convenient to read and troubleshoot with your user manual. That is why we have improved our services to allow you watch and follow some steps in solving problems as they arise.

If you encounter further problems or want to see another issue resolved, please send an email to enquiry@focusun.com with the video/problem topic and we will make a video demonstration for your reference.

Vacuum Cooling System

- What is Vacuum Cooling?

- Vacuum Cooling technology is based on the phenomenon that water starts boiling at lower temperatures as the pressure decreases. The boiling process takes away heat from the product. As a result, products can be cooled down to 0.5 ℃ within 20 – 30 minutes. Even micro-perforated, packed products can easily be cooled this way!

- What are the advantages of Vacuum Cooling?

- The quick and uniform cooling (the surface and core of the vegetable can reach exact the same temperature after vacuum cooling) results in a longer shelf life of your produce. At the same time, you can save energy costs, as the vacuum cooling process is much more cost-effective than traditional cooling technologies.

- What are Vacuum Coolers applied for?

- The vacuum cooling process working perfectly for field-packed leafy produce, fresh cut-flowers, and pre-cooked food which can minimize the activity of spoilage bacteria and extend the shelf-life to a great extent.

- What are available refrigeration systems?

- Focusun Ice Machines are available with a variety of refrigeration systems : air cooled, water cooled and ammonia system.

- After pressing start button, the ice maker running indicating light is off and the ice maker isn't running?

- Find out the reason of this breakdown by doing following steps. Check whether the electrical source breaks off. Examine whether the fuse blows; Check whether the emergency stop button is pressed. If this fails to be the case, please contact Focusun After-Sales-Team for your solutions.

- What do I do in case of power shortage?

- First turn off your machine using the PLC Control. Then switch of the main power supply and unplug the connecting cable if necessary. Leave your machine stationary until the power shortage is solved. Now in a reverse cycle, plug the connecting power supply cable and switch on the main power supply. Leave this for 1-2 minutes and then turn on your PLC Control. Your machine should be working normally now.

- My machine is malfunctioning but the PLC Control doesn't indicate the problem?

- The PLC Control will typically indicate a problem with your machine with amber or red light on your PLC Control. If you have problem in your machine but the PLC Control is not indicating, please reboot your PLC Control by switching it off for 5-10 minutes. Restart your PLC Control and your machine should be working or indicating the error now. If this fails to be the case, please contact your own professional engineer or contact your professional and friendly Focusun After-Sales-Team for your solutions.

- Why is the compressor disturbance indicator light on?

- Check whether wires are loose, there is lack of phrase and whether the set value is normal. Check whether the compressor has over heated. After the motor is cooling down, it will reset automatically; Replace compressor temperature control module. Check whether cooling system is running normally, if not, condenser needs cleaning. Check high/low pressure set value or change high/low pressure switch.

Vacuum Cooling System for Ni's INT

Focusun Vacuum Cooler to cool down roses for further processing

Also read:

Block Ice plant Tube Ice Plant Flake Ice Plant Cube Ice Plant Plate Ice Plant

For newly harvested products like fruits, vegetables or flowers, the way of reducing internal field temperature to ideal storage temperature is a key step to maintain freshness and longevity. As traditional cooling methods have several drawbacks, we introduced a new type of refrigeration technology at Focusun: the Vacuum Cooler. Offering shorter processing time, high temperature uniformity, more efficiency in throughput without damaging the produce.

In February 2014, a large Asian producer of rose buds wanted to increase their efficiency and lower costs by updating their post harvest refrigeration system to a Focusun Vacuum Cooler. The rose buds are used for tea making and therefore increasing the high product quality was the goal. We were happy to help making rose tea more intensive in taste.

Project Summary

Challenge: Reducing the rose buds' temperature for optimal storage and transportation, ensuring a careful product treatment.

- The reduction in temperature via vacuum cooler is achieved by rapid evaporation of water after the atmospheric pressure inside the chamber is lowered by a vacuum pump. This achieves a uniform cooling preservation effect.

- Focusun vacuum cooler can significantly improve the cooling rate, reduce the wastage of nutrients and keep original texture, color, sensory properties and nutrition of products, which can significantly increase the shelf life of products as well as reducing the health risk caused by organism growth.

Our solution: Implementing a Vacuum Cooler to achieve the best product quality, while being efficient in energy consumption.

- We deployed our Focusun Vacuum Cooler FVC-10P with a capability of 10 pallets and a volume of 40 m3, L6000×W2950×H2250 mm (internal usable size of VC chamber) to handle the quantity. The size of a pallet is 1.1m × 1.4m × 2.2m with circulating boxes on each pallet: 7 boxes per layer, 6 layers per pallet.

- This Vacuum Cooler will reduce the temperature: from 38℃ to 4-6℃ (equals 100°F to 40°F), settled temperature can be adjusted, with a minimum temperature of 0.5℃ (33°F). With a capacity of 4.4T/20mins, the theoretical capacity is 13.2T/H (20mins per each treatment). To maximize efficiency we installed a Trolley loading system to minimize down time between loads.

- Safe and stable: we import electric components like Vacuum pumps from Busch (Germany) and use SUS304 & t8 materials to ensure a long life of our product. Guaranteed.

Contacts & Support

Focusun Refrigeration CorporationRoom 603, Baohong Center

No. 7755 Zhongchun Rd

Shanghai CHINA

ZipCode: 201100

Tel: +86-21-5108 9946

Fax: +86-21-5227 2259

Email: enquiry@focusun.com

Sales: sales@focusun.com

Marketing: marketing@focusun.com

Press: press@focusun.com

Newsletter: newsletter@focusun.com